- de

- en

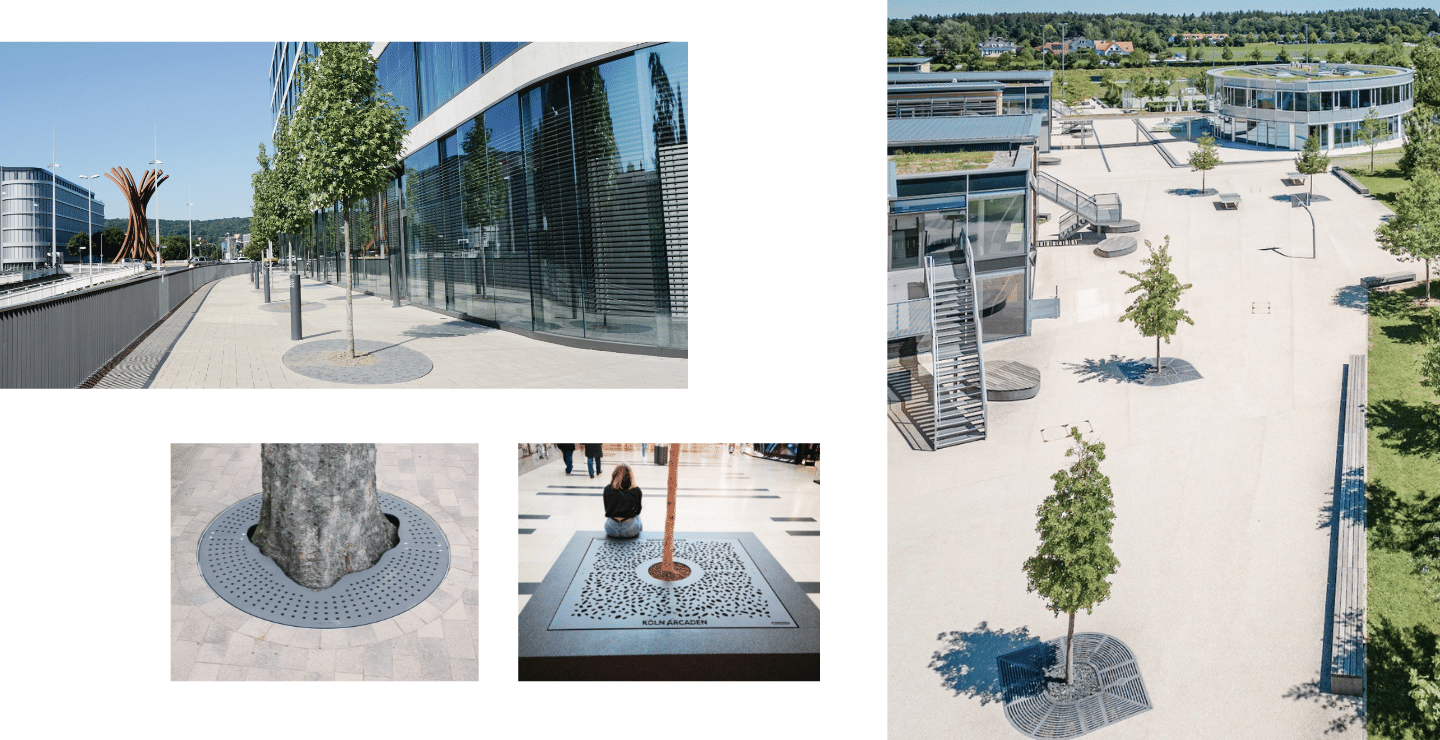

Neckarsulm | Amorbacher Straße

Our laser gratings are the crowning glory of a planting pit. They come in round, square, rectangular or organically shaped and protect the upper root area.

They are available in various materials and, if required, have an anti-slip coating in accordance with the BGR guidelines. In addition to their function as tree protection, they also serve as supports for different models of in-ground lights for a variety of manufacturers.

However, the main argument for laser grating is the endless variety of variations thanks to the most modern laser cutting process. This enables both the smallest production sizes and the realization of your customized design.

The HUMBERG laser gratings are 99% recyclable and designed for a wheel load of 1.5 t to 5 t.

Laser gratings are convincing when individuality is to be combined with root protection. For example, with historical paving that has unusual shapes or existing trees are not in the center of the planting pit.

By default, the grates are laid on a concrete foundation and are screwed to a plaster stop edge located on top. There are four system variants, which differ primarily in their type of foundation. With the fully equipped HUNO® TreeCare, an ideal gas exchange takes place in the root area by means of the air caps, via the ventilation supports and distribution in the root star.

The side rail consisting of HUNO® Biotextil biodegrades over time and does not stand in the way of natural root growth. Compaction of the soil is avoided by the insertable inner segment and, depending on the design, can be adapted to the increase in thickness of the trunk.

Laser rust

Mulch fleece

Perforated plate

Supporting structure

Outer frame

Concrete foundation

Fasteners

| CONSISTING OF | |

| Laser rust | Sheet steel S235JR (EN DIN 10 027 -1) with a watering opening consisting of a 3mm stainless steel cover, powder-coated DB 703 iron mica fine structure, slip resistance according to the guidelines of DIN 51130 in class R10 or HUNO® ASPERO coating, registered design, class R12 (test method " Inclined Plane" and salt spray test) in the same color tone |

| Mulch fleece | For protection against weeds growing through (registered design - DBGM) |

| Perforated plate | For more sure-footedness and less maintenance |

| Inner segment | Welded profile tube construction as supporting frame, made of steel S235JR (EN DIN 10 027-1) for up to 5.0 t wheel load, hot-dip galvanized according to DIN EN ISO 1461 with a lead-free zinc melt (zinc content of 98%) |

| Outer frame | Outer frame, screwed in several parts, made of sheet steel S235JR (EN DIN 10 027-1), hot-dip galvanized according to DIN EN ISO 1461 with a lead-free zinc melt (zinc content of 98%) for screwing onto the concrete foundation |

| concrete foundation | 4-part, 25 cm high, 16 cm wide incl. reinforcement with Q 188 A stirrup cage up to 5 t wheel load, material: C 35/45 with high water penetration resistance, with cast-in threaded sleeves for transport and assembly |

| Connectors | Screws, washers, dowels etc. |

SQUARE LENGTH X WIDTH IN CM | ROUND DIAMETER IN CM | TRUNK NECK OPENING IN CM ROUND | SQUARE IN CM |

| 125 x 125 | Ø 125 | 50 | 70 oder 80 |

| 150 x 150 | Ø 150 | 50 | 70 oder 80 |

| 180 x 180 | Ø 180 | 50 | 70 oder 80 |

| 200 x 200 | Ø 200 | 50 | 70 oder 80 |

| 250 x 250 | Ø 250 | 50 | 70 oder 80 |

| 300 x 300 | Ø 300 | 50 | 70 oder 80 |

OR PROJECT-SPECIFIC MANUFACTURING |