- de

- en

Weimar | Bauhausmuseum

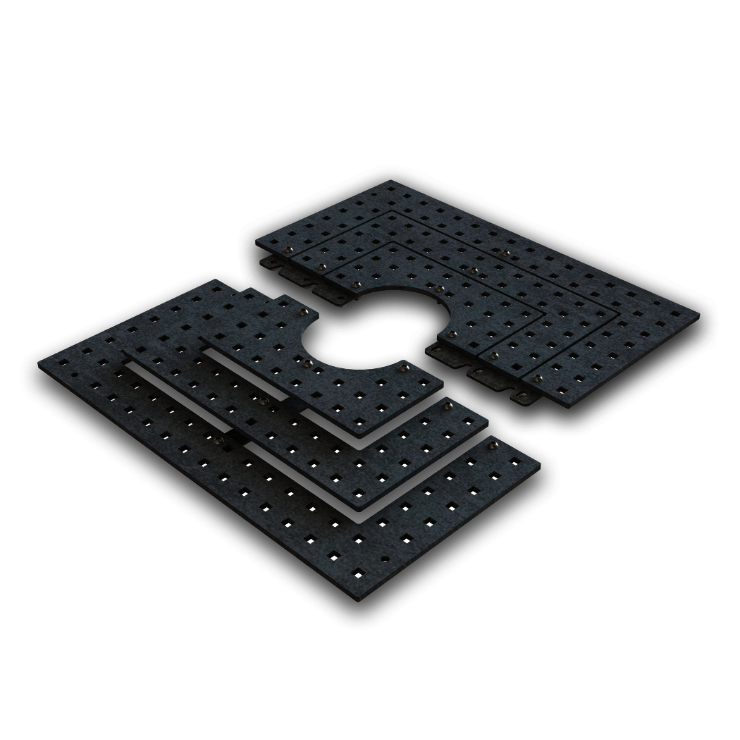

Trunk foot edges offer the ideal finish in a paved area or in a surface grid. The benefit is that the opening is close to the trunk and thereby pollution by waste or weeds is prevented. Maintenance costs are reduced accordingly. Due to the multi-part production method, individual segments can be removed.

Trunk base edgings are an ideal finish, preventing tripping hazards caused by exposed planting pit openings.

The trunk foot edge consist of multi-part steel elements and are manufactured individually according to the construction situation. If, for example, the tree sits slightly offset in the planting pit, the closing can be adjusted accordingly. They are made of hot-dip galvanized steel according to DIN EN ISO 1461 and powder-coated. You may choose from many RAL colors, sizes or designs.

Trunk foot edging

Fasteners

| CONSISTING OF | |

| Steel base surround | Steel S235JR according to EN DIN 10 027 -1), hot-dip galvanized with anti-slip powder coating R10 according to BGR 181 or HUNO® ASPERO coating, registered utility model, class R12 |

| Trunk foot edging made of weatherproof structural steel | Iron oxide surface |

| Fasteners | Screws, washers, dowels etc. |

| SQUARE IN CM | ROUND DIAMETER IN CM | STEM NECK OPENING ROUND | SQUARE IN CM |

| 50 x 50 | Ø 50 | 30 or 40 |

| 60 x 60 | Ø 60 | 30 or 40 |

| 70 x 70 | Ø 70 | 30 or 40 |

| 80 x 80 | Ø 80 | 30 or 40 |

OR PROJECT-SPECIFIC MANUFACTURING |